Iron and Steel Technology in Japanese Arms & Armors - Part 3: Bladesmithing

Iron and Steel Technology in Japanese Arms & Armors - Part 3: Bladesmithing

Introduction

Finally, after a very long time, I'm able to continue with this series; it took a lot of efforts and it was a very hard topic to research, despite the amount of sources available on the net and before getting to the article itself, I would like to spend some words about this specific field: Japanese traditional sword making.

To make the long story short, it was extremely complicated because most of the so called modern days traditional Japanese sword making is related to the Shinshintō (新々刀) tradition, which was developed around the 1764.

This is quite late for the period in which my study was focused, the 16th century; moreover there was a dramatic shift in terms of design from the functionality of the sword to the aesthetic and artistic value of the weapon. So not only swords were made from different materials, but the main concern of the maker wasn't a functional sword made for combat, but a beautiful one.

One key examples of this focus is the creation of very wide, beautiful hamon patterns (the hardened zone of the sword-more of this later) that undermined the structural integrity of the sword, as noted by Suishinshi Masahide, a contemporary smith of the Shinshintō era.

So in order to create beautiful swords, functionality was sacrificed.

To make the long story short, it was extremely complicated because most of the so called modern days traditional Japanese sword making is related to the Shinshintō (新々刀) tradition, which was developed around the 1764.

This is quite late for the period in which my study was focused, the 16th century; moreover there was a dramatic shift in terms of design from the functionality of the sword to the aesthetic and artistic value of the weapon. So not only swords were made from different materials, but the main concern of the maker wasn't a functional sword made for combat, but a beautiful one.

One key examples of this focus is the creation of very wide, beautiful hamon patterns (the hardened zone of the sword-more of this later) that undermined the structural integrity of the sword, as noted by Suishinshi Masahide, a contemporary smith of the Shinshintō era.

So in order to create beautiful swords, functionality was sacrificed.

Nowadays, said swords are still evaluated for their artistic value rather than for their performances, and the attitude towards the shintō tradition has led many enthusiast of this world to spread misconceptions that I would like to debunk in this article.

A wide hamon on a Japanese sword.

As clichè as it might be ( a personal suggestion: never thrust someone who claims that everyone is wrong while he is the only one with the "Truth" in his pocket) there are some factual realities that need to be addressed, like the fact that Kotō (古刀) swords were stronger and much more functional-oriented than their shintō era counterpart, and that the whole view (performance wise) of the so called traditional Japanese sword is highly under represented because of that bias.

These are not words of mine, but it was already pointed out by Kōkan-Nagayama in the post WW2 Japan, when the swordsmith tradition was re-established

(References:

"The Functionality of Nihonto" by Suishinshi Masahide

"The Outline of a Japanese sword"

"The Connoisseur's Book of Japanese Swords" by Kōkan-Nagayama)

As always, in case you missed, I've already talked about the raw iron sources found in Japan and the processes used to smelt said sources into iron and steel ingots in the 16th century; I highly suggest you to read them to better understand this article.

Please also keep in mind that there were several blade's making traditions, and this post won't represent all of them naturally. It is also fair to point out that the manufacturing of these blades was applied not only to swords, but for any type of edged Japanese weapons.

A wide hamon on a Japanese sword.

As clichè as it might be ( a personal suggestion: never thrust someone who claims that everyone is wrong while he is the only one with the "Truth" in his pocket) there are some factual realities that need to be addressed, like the fact that Kotō (古刀) swords were stronger and much more functional-oriented than their shintō era counterpart, and that the whole view (performance wise) of the so called traditional Japanese sword is highly under represented because of that bias.

These are not words of mine, but it was already pointed out by Kōkan-Nagayama in the post WW2 Japan, when the swordsmith tradition was re-established

(References:

"The Functionality of Nihonto" by Suishinshi Masahide

"The Outline of a Japanese sword"

"The Connoisseur's Book of Japanese Swords" by Kōkan-Nagayama)

As always, in case you missed, I've already talked about the raw iron sources found in Japan and the processes used to smelt said sources into iron and steel ingots in the 16th century; I highly suggest you to read them to better understand this article.

Please also keep in mind that there were several blade's making traditions, and this post won't represent all of them naturally. It is also fair to point out that the manufacturing of these blades was applied not only to swords, but for any type of edged Japanese weapons.

Before I start, here the usual disclaimer;

I might have missed something here and there, and I might be wrong since I don't have neither the experience nor the academic background to be precisely accurate. Please take these information with a "pinch of salt".

Despite this limitation, I'm using academic references that you can find throughout the article to back up my thesis.

"The Craft of the Japanese sword" by Leon and Hiroko Kapp and Yoshindo Yoshihara )

Choose the structure of the blade

This is one of, if not the most, important step of the whole process and it's here that we have the first misconceptions to address.

If you are familiar with Japanese swords, you cannot have never ever heard the concept of lamination which states that: "traditional Japanese blades were made with a combination of hard and soft steels carefully assembled in order to create a perfectly balanced blade."

This is true, to some extent; but it's not the only historical way of creating a Japanese blade and over the ages, this whole concept of the lamination has been inflated and mystified with wildly inaccurate statements.

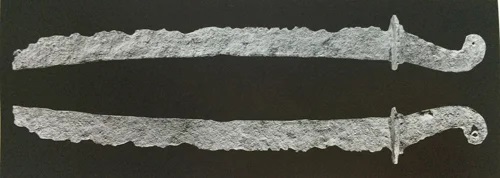

First of all, this method is the basic of sword making since the early Iron Age and was definitely not unique to Japan.

Second, it doesn't create a stronger blade by default and while it has some benefits, it has some serious flaws as well.

Third, throughout the entire sword history elsewhere in the world, the process was to create a laminated structure of different types of steel (and possibly iron) at the beginning when technology was still very primitive, and then switch to all steel, and possibly mono steel ( a single piece of steel) constructions; but in Japan, the average "history" book claims otherwise, with early Jokoto swords being made with a single (inferior) piece of steel and then with the development of the Nihonto, there was a shift towards the lamination process.

This is partially true; lamination started to be codified and pushed forward by the Shogunate with the Shinto and Shinshinto traditions from the 17th century onward, but it doesn't apply to previous centuries!

It is also quite nonsensical to point out that earlier swords, being made with primitive technology, were made with a method (all steel/monosteel construction) that required advanced technology!

This whole attitude had led the Japanese sword enthusiasts to erroneously claim that:

a) Monosteel swords are inferior (a.k.a. type "lamination katana" on google and see the wikipedia picture with maru kitae - monosteel sword- being called "the poorest method".

b) Japanese swords were never made with a monosteel structure because of that (this is also related to people who deliberately want to bash on the Japanese sword).

c) The more complex the lamination - the better the sword.

The infamous picture I've mentioned above; the "orikaeshi san mai" doesn't make sense (a weld on the edge?! Seriously?!) and the famous soshu kitae was never found in any swords analyzed. It is also likely that the labels of medium and soft steel are not applied correctly here; in any case, there is a detailed picture of the structures observed below in the article.

So to address all these points briefly: a) this is quite the opposite; monosteel swords are structurally stronger according to Alan Williams, because they don't have weld lines in the material that weaken the integrity of the blade, b) Japanese blades were also made with a monosteel structure and c) this is simply not true, beside some of the so called incredibly hard laminated structure were never observed in reality and have no real advantages over the simplistic ones.

So from now on, I will cover the two forging process separately.

Lamination method

This is the mainstream method associated with Japanese sword making, and it was the bread&butter of sword making since steel swords started be a thing historically.

The concept itself is related to economic issues; with a bloomery based technology (see my previous part about smelting processes), creating high and medium carbon steel was quite hard and expensive: only a small amount of the bloom was composed of that type of steel, which was required to create good swords with good edge, capable of being hardened. On top of that, the forging process itself wasn't efficient at all, so much of the material was lost during the making.

Even with blast furnaces, high carbon steel required some efforts to be produced up until the 18th century.

Within that context, it makes so much sense to use the expensive part only where its needed, namely the edge, and create the rest with less expensive materials, like wrought iron which is essentially low carbon steel.

This why lamination was so common prior to the 18th century, all over the world.

The combinations are the following:

Hard steel edge welded to an iron core, a hard steel skin that encase an iron core, a hard edge welded on a low carbon steel core, and a hard skin encasing a low carbon steel core.

There is a bit of variation here and there, but these are the main categories more or less used by Japanese smiths (and I would add, used by their European counterparts too) by the 16th century, and are ordered from lowest to higher quality.

The last two could be considered all steel swords.

The lamination styles observed on cross sections of Japanese swords; the last two are all steel swords. There are occasionally some others variations like different types of steel on the sides or in the back, although it's hard to establish whether or not this type was used in the 16th century.

Lamination has a price though; the fact that you need to weld two materials of different carbon contents introduce welding lines in the balde, which could led to potential failure. In fact, according to some tests done by A.Williams, with all else being equal (an impossible condition to obtain while talking about pre-modern world swords) a laminated sword is weaker compared to one made with one piece of steel.

Despite this limitation, I'm using academic references that you can find throughout the article to back up my thesis.

Last time I've explained the various type of steel ingots produced by the Tatara, both in a direct steel making process as well as an indirect one, and this is precisely the point where this article start.

Although the steel ingots would have changed in terms of chemical compositions (sagegane would have been of higher quality - less slag - compared to tamahagane), the steel would have still be rather heterogeneous with slag inclusions, at least compared with modern steel.

This is quite important: prior to the 19th century, pure steel in the sense of no slag inclusions was impossible to obtain, all over the world possibly with the exception of Indian crucible steel.

So the smith received various grade of steel, either tamahagane or sagegane as well as lower carbon steel known as hocho tetsu and possibly iron ingots too. This is where the creation of the blade start.

Selection of the steel

The first thing the smith had to do was sorting out how much carbon the various grade of steel had. In fact, due to the pre-modern technology, each ingots had an uneven carbon distribution. To do so, the artisan heated the various ingots and hammered them on the anvil, which surface was covered with water; this process is called mizubeshi (水べし).

All the ingots were turned into plates, heath and then quenched (cooled very rapidly) into water in order to harden them.

This process was also used to consolidate the bloom if the starting material was tamahagane (high carbon bloomery steel).

Once all the plates were ready, he broke them into several pieces; this process is called kowari (小割り) and was mandatory in order to establish the carbon content of each piece.

If the steel had high carbon, the fracture would have look very sharp and the plate would have been very brittle.

On the other hand, if the steel had a lower amount of carbon, the fracture would have look like a deformation and the material would have been much more easier to bend.

Moreover, the color of the steel would have differ due to the carbon concentration.

On a side note, the high carbon steel pieces, either tamahagane or sagegane, will still have a very high carbon content (possibly around 1% or more) which is still too high for blade making, and need further refinement.

Broken steel "tiles" of various carbon content; picture taken from here

At the end of the process, the smith knew precisely which kind of steel he had to work with, from very high carbon steel to wrought iron. At this point, the smith made a tool called tekoita (梃子板) which is simply a long handle in which a small plate of steel was welded in order to create the foundation of the billet.

The teko was suppose to accomodate all the various pieces of steel in a piled structure.

(References:

"Tatara and the Japanese sword: the science and technology" by Tatsuo Inoue

Although the steel ingots would have changed in terms of chemical compositions (sagegane would have been of higher quality - less slag - compared to tamahagane), the steel would have still be rather heterogeneous with slag inclusions, at least compared with modern steel.

This is quite important: prior to the 19th century, pure steel in the sense of no slag inclusions was impossible to obtain, all over the world possibly with the exception of Indian crucible steel.

So the smith received various grade of steel, either tamahagane or sagegane as well as lower carbon steel known as hocho tetsu and possibly iron ingots too. This is where the creation of the blade start.

Selection of the steel

The first thing the smith had to do was sorting out how much carbon the various grade of steel had. In fact, due to the pre-modern technology, each ingots had an uneven carbon distribution. To do so, the artisan heated the various ingots and hammered them on the anvil, which surface was covered with water; this process is called mizubeshi (水べし).

All the ingots were turned into plates, heath and then quenched (cooled very rapidly) into water in order to harden them.

This process was also used to consolidate the bloom if the starting material was tamahagane (high carbon bloomery steel).

Once all the plates were ready, he broke them into several pieces; this process is called kowari (小割り) and was mandatory in order to establish the carbon content of each piece.

If the steel had high carbon, the fracture would have look very sharp and the plate would have been very brittle.

On the other hand, if the steel had a lower amount of carbon, the fracture would have look like a deformation and the material would have been much more easier to bend.

Moreover, the color of the steel would have differ due to the carbon concentration.

On a side note, the high carbon steel pieces, either tamahagane or sagegane, will still have a very high carbon content (possibly around 1% or more) which is still too high for blade making, and need further refinement.

Broken steel "tiles" of various carbon content; picture taken from here

At the end of the process, the smith knew precisely which kind of steel he had to work with, from very high carbon steel to wrought iron. At this point, the smith made a tool called tekoita (梃子板) which is simply a long handle in which a small plate of steel was welded in order to create the foundation of the billet.

The teko was suppose to accomodate all the various pieces of steel in a piled structure.

Various pieces of steel piled on top of the tekoita; take from here

(References:

"Tatara and the Japanese sword: the science and technology" by Tatsuo Inoue

"The Craft of the Japanese sword" by Leon and Hiroko Kapp and Yoshindo Yoshihara )

Choose the structure of the blade

This is one of, if not the most, important step of the whole process and it's here that we have the first misconceptions to address.

If you are familiar with Japanese swords, you cannot have never ever heard the concept of lamination which states that: "traditional Japanese blades were made with a combination of hard and soft steels carefully assembled in order to create a perfectly balanced blade."

This is true, to some extent; but it's not the only historical way of creating a Japanese blade and over the ages, this whole concept of the lamination has been inflated and mystified with wildly inaccurate statements.

First of all, this method is the basic of sword making since the early Iron Age and was definitely not unique to Japan.

Second, it doesn't create a stronger blade by default and while it has some benefits, it has some serious flaws as well.

Third, throughout the entire sword history elsewhere in the world, the process was to create a laminated structure of different types of steel (and possibly iron) at the beginning when technology was still very primitive, and then switch to all steel, and possibly mono steel ( a single piece of steel) constructions; but in Japan, the average "history" book claims otherwise, with early Jokoto swords being made with a single (inferior) piece of steel and then with the development of the Nihonto, there was a shift towards the lamination process.

This is partially true; lamination started to be codified and pushed forward by the Shogunate with the Shinto and Shinshinto traditions from the 17th century onward, but it doesn't apply to previous centuries!

It is also quite nonsensical to point out that earlier swords, being made with primitive technology, were made with a method (all steel/monosteel construction) that required advanced technology!

This whole attitude had led the Japanese sword enthusiasts to erroneously claim that:

a) Monosteel swords are inferior (a.k.a. type "lamination katana" on google and see the wikipedia picture with maru kitae - monosteel sword- being called "the poorest method".

b) Japanese swords were never made with a monosteel structure because of that (this is also related to people who deliberately want to bash on the Japanese sword).

c) The more complex the lamination - the better the sword.

The infamous picture I've mentioned above; the "orikaeshi san mai" doesn't make sense (a weld on the edge?! Seriously?!) and the famous soshu kitae was never found in any swords analyzed. It is also likely that the labels of medium and soft steel are not applied correctly here; in any case, there is a detailed picture of the structures observed below in the article.

So to address all these points briefly: a) this is quite the opposite; monosteel swords are structurally stronger according to Alan Williams, because they don't have weld lines in the material that weaken the integrity of the blade, b) Japanese blades were also made with a monosteel structure and c) this is simply not true, beside some of the so called incredibly hard laminated structure were never observed in reality and have no real advantages over the simplistic ones.

So from now on, I will cover the two forging process separately.

Lamination method

This is the mainstream method associated with Japanese sword making, and it was the bread&butter of sword making since steel swords started be a thing historically.

The concept itself is related to economic issues; with a bloomery based technology (see my previous part about smelting processes), creating high and medium carbon steel was quite hard and expensive: only a small amount of the bloom was composed of that type of steel, which was required to create good swords with good edge, capable of being hardened. On top of that, the forging process itself wasn't efficient at all, so much of the material was lost during the making.

Even with blast furnaces, high carbon steel required some efforts to be produced up until the 18th century.

Within that context, it makes so much sense to use the expensive part only where its needed, namely the edge, and create the rest with less expensive materials, like wrought iron which is essentially low carbon steel.

This why lamination was so common prior to the 18th century, all over the world.

The combinations are the following:

Hard steel edge welded to an iron core, a hard steel skin that encase an iron core, a hard edge welded on a low carbon steel core, and a hard skin encasing a low carbon steel core.

There is a bit of variation here and there, but these are the main categories more or less used by Japanese smiths (and I would add, used by their European counterparts too) by the 16th century, and are ordered from lowest to higher quality.

The last two could be considered all steel swords.

The lamination styles observed on cross sections of Japanese swords; the last two are all steel swords. There are occasionally some others variations like different types of steel on the sides or in the back, although it's hard to establish whether or not this type was used in the 16th century.

Lamination has a price though; the fact that you need to weld two materials of different carbon contents introduce welding lines in the balde, which could led to potential failure. In fact, according to some tests done by A.Williams, with all else being equal (an impossible condition to obtain while talking about pre-modern world swords) a laminated sword is weaker compared to one made with one piece of steel.

However, there are advantages in using a lamination structure, compared to a monosteel sword.

Not to mention that welding steel need a lot of skill and expertise with that level of technology.

In fact, if you chose to make the sword out of a single material, you cannot have different carbon content across the blade so you need to chose an optimal level, which is around 0.4 and 0.6 %.

Otherwise you risk to compromise the structure integrity of the blade with a higher content, because the steel would be too hard and thus too brittle ( which means that under shocks it has a tendency to snap).

On the other hand, with a lamination structure, you could use a higher carbon content on the edge, because said steel is supported by a softer material that will react in a different way to the shocks, preventing the sword to snap in two and limiting any potential damage only to the edge.

The reason why you want a higher carbon level in the edge, like 0.6 or 0.8, is that you can achieve higher hardness through hardening and so in theory a sharper edge, and said edge would stay sharper for longer periods through usage.

Moreover, if two edges collide in a perpendicular angle (practically impossible to achieve in a sword fight of any kind) the harder ones could bite into the softer ones, without being damaged.

In theory, a sword with a harder edge could perform better in the cut, but the performance is heavily dependent on other factors like edge geometry, skill of the wielder and so on. So there are small trade offs to evaluate when choosing which structure using.

If the smith chose to create a laminated blade (which was done quite a lot; the majority of the blade used in the world by the 16th century had this feature due to the lower cost of production) he would need to work with two separate billets: the kawagane (皮鉄) which is the outer layer and the shingane (心鉄) which is the inner core.

Let's supposed that he would work on a kobuse, one of the most popular lamination style: hard steel jacket and low carbon steel core.

The first thing he has to do is to separate the two grades of steel he wanted to use and piled them into two different tekoita.

So when he worked to his kawagane, he only piled high carbon steel.

If you remember, as I've stated before in this article and in the previous one, the high carbon steel used in both cases (tamahagane or sagegane) is too high for sword making. On top of that, throughout the piled structure you will have different bits with different carbon so you have to homogenize the billet.

In order to do so, the smith wraps the steel pieces with Japanese paper, and a mixture of clay and rice straw's ashes; every school has its own recipe when it comes to these elements but the principle is the following: having something to stabilize all the pieces, allow the pieces to be heated evenly and using the ashes to prevent too much decarburization - you want the high carbon steel to lower its C% just a little bit, because further carbon will be burned through forging.

Not to mention that welding steel need a lot of skill and expertise with that level of technology.

In fact, if you chose to make the sword out of a single material, you cannot have different carbon content across the blade so you need to chose an optimal level, which is around 0.4 and 0.6 %.

Otherwise you risk to compromise the structure integrity of the blade with a higher content, because the steel would be too hard and thus too brittle ( which means that under shocks it has a tendency to snap).

On the other hand, with a lamination structure, you could use a higher carbon content on the edge, because said steel is supported by a softer material that will react in a different way to the shocks, preventing the sword to snap in two and limiting any potential damage only to the edge.

The reason why you want a higher carbon level in the edge, like 0.6 or 0.8, is that you can achieve higher hardness through hardening and so in theory a sharper edge, and said edge would stay sharper for longer periods through usage.

Moreover, if two edges collide in a perpendicular angle (practically impossible to achieve in a sword fight of any kind) the harder ones could bite into the softer ones, without being damaged.

In theory, a sword with a harder edge could perform better in the cut, but the performance is heavily dependent on other factors like edge geometry, skill of the wielder and so on. So there are small trade offs to evaluate when choosing which structure using.

If the smith chose to create a laminated blade (which was done quite a lot; the majority of the blade used in the world by the 16th century had this feature due to the lower cost of production) he would need to work with two separate billets: the kawagane (皮鉄) which is the outer layer and the shingane (心鉄) which is the inner core.

Let's supposed that he would work on a kobuse, one of the most popular lamination style: hard steel jacket and low carbon steel core.

The first thing he has to do is to separate the two grades of steel he wanted to use and piled them into two different tekoita.

So when he worked to his kawagane, he only piled high carbon steel.

If you remember, as I've stated before in this article and in the previous one, the high carbon steel used in both cases (tamahagane or sagegane) is too high for sword making. On top of that, throughout the piled structure you will have different bits with different carbon so you have to homogenize the billet.

In order to do so, the smith wraps the steel pieces with Japanese paper, and a mixture of clay and rice straw's ashes; every school has its own recipe when it comes to these elements but the principle is the following: having something to stabilize all the pieces, allow the pieces to be heated evenly and using the ashes to prevent too much decarburization - you want the high carbon steel to lower its C% just a little bit, because further carbon will be burned through forging.

This process is known as tsumiwakashi (積み沸かし).

The billet is then heated in the forge at a temperature of 1300 °C and when the steel has a bright white color, it is taken out and hammered gently to create a single piece. The process might be repeated more than once until the piled structure is fully welded and a single piece is formed.

The piled structure covered with the pasty mixture.

The same is done with the shingane, but instead of high carbon steel, wrought iron or low carbon steel is used.

Both billets are still be quite heterogeneous and as far as the kawagane is concerned, there is still too carbon; these problems will be addressed in the next step, which is forging&folding.

Single steel method

As I have explained above, lamination was not the single method used to make Japanese blades, nor the best one.

Swords from the 16th and previous centuries have been analyzed by various authors, to name one Cyril Stanley Smith, where the carbon content was the same throughout all the sword, around 0.5%. This mean that the blade was created with one single type of steel, just like their counterparts in other parts of the world.

With cross section, it was possible to observe a blade made without the lamination method but with a single block of material.

Were these swords inferior? No, absolutely, not in terms of strength.

In fact they didn't had the welding lines inside the material, and so no possible failure point; on the other hand, they had a softer edge which is by no means a pure disadvantage especially when said swords were supposed to be used against armor, unlike the later ones.

These swords were actually much more expensive to make, because the steel required was of high/medium carbon content and composed the entire blade rather than only the edge.

Why these swords have been ignored by most enthusiasts is still a mystery, but I won't dare to speculate in that direction.

Nowadays, smiths like Yasuhiro Kobayashi still use this method.

Another famous picture taken from the web (source); it is possible to see swords made in the medieval period being made with one piece of steel. This structure was also choose for 16th century swords as observed by other authors.

In this case the smith wouldn't make two separate billets, but just a single one, using either one single high/medium carbon type like sagegane in the piled structure or kneading together very hard carbon steel with lower carbon steel in an alternate layered structure.

Both method aim to obtain the same thing: one fairly homogeneous steel with a single medium carbon content throughout the whole blade.

The process is the same described before, so the piled structure is wrapped with the clay-ashes-paper mixture, heated and hammered into a single plate.

Once the process is over, the billet is ready to be forged and folded to create the basic shape of the sword.

This is how the heated piled structure look like; picture taken from here

(References:

"The sword and the crucible: a history of the metallurgy of European swords up to the 16th century" by Alan Williams

"The outline of Japanese Swords"

"The Craft of the Japanese sword" by Leon and Hiroko Kapp and Yoshindo Yoshihara

"The Knigth and the Blast furnaces" by Alan Williams)

Forging & Folding the steel

The other often misunderstood process about Japanese sword making is the folding , in Japanese orikaeshi kitae ( 折り返し鍛え).

Folding the steel is mandatory in order to lower the carbon content of the high carbon steel billet, homogenize the steel, reducing the number of slag inclusions and making them less harmful to the blade integrity.

Screenshot taken from the amazing video done by AWEme, source here

One of the biggest, very old misconception is that folding create a stronger steel: true, but only in a pre-industrial revolution world and I will explain why. However if the starting material is homogeneous enough, you don't need to fold the billet to create a stronger blade so folding steel in terms of functionality doesn't make any sense with anything produced by a modern age blast furnace.

Another big misconception is that folding is not necessary when an indirect steel process making is used: again true, but not before the 18th century.

Although I have already addressed the topic in the previous article, blast furnaces technology will create a better steel (in the Japanese context, the Zuku oshi tatara method) compared to a bloomery furnace, but during the fining process (turning cast iron into steel), impurities will be reintroduced in the steel and the carbon content will be uneven across the new ingots.

So even if the amount of slag would be lower, you will still have slag in the steel (namely, finery inclusions).

This is why Chinese sword making, despite using blast furnaces technology since the Han dynasty, involved folding. Actually, pretty much of the world's sword tradition used that technique to improve the quality of the steel.

Another misconception is that folding and pattern welding are the same thing; this is simply not true, the two processes are quite different in reality.

Despite of lamination/single steel being used, the process is fairly similar.

The first folding is called shitagitae (下鍛え); the steel billet is heated again to welding temperature, hammered into a plate and then the smith with the aid of his students use a blade or a similar tool to cut a notch in the middle of the plate. The cut shouldn't be able to separate the material into two blocks, but should be deep enough.

Then the plate is turned around and the two extremities hammered on top of each other, to create a single plate again.

When the steel billet is heated, it reacts with oxygen in the air and forms dark scales that are visible on the surface; it is extremely important that said scale won't end up in between the folded blocks. Those scales are rust, and having them in between the layers of the steel would be harmful to the blade structure.

To avoid that, the smith use a brush made of a wet tatami mat.

This process is repeated more than once; every time the steel is folded, it loose carbon, said element is spread evenly across the billet, and the slag inclusions are squeezed out from the material.

In fact to avoid excessive carbon loss, the billet could be wrapped again with clay.

It is also possible that folding improves the strength of the steel due to obtaining smaller grain size in the material, since it was observed that some Japanese blades had different grain size on the edge, but this doesn't seem to be the case and this fact might be related to the heath treatment instead.

It is fair to notice that is almost impossible to prevent minimum amount of rust inside the layers, and each fold while removing inclusions, it also add a little amount of harmful material. So while folding is extremely important at the beginning, after a certain level it start to be detrimental.

At the end of the process, the slag content was quite low on the best example; some steel artifacts had a % of slag closer to 0% although munition grade quality was present as well.

A billet being folded during the forging process; notice the dark scales on the surface.

After the initial shitagitae is done, the smith performs another type of folding called agegitae (上げ鍛え), which includes folding into different orientation so the cut could be done in a vertical direction or in diagonal directions.

Every time before performing a fold, the block needs to be heated at the right temperature and due to the loss of carbon it start to be harder and harder to forge; this aid the smith to understand when its time to end the process.

The optimal number of folding, which take into account the carbon loss, is around 13 if the smith is working with a high carbon billet and 10 with a low carbon steel one, although if pure iron is used the smith don't have the problem of carbon loss.

Since folding creates layers in between the steel, with an exponential growth, it adds beauty to the surface of the steel and each school create beautiful pattern that could be appreciated even nowadays. Said patterns would be revealed thanks to the Japanese art of polishing their blades.

Possible folding directions

If the smith is not satisfied with its final billet, he can cut it into 4 different pieces, stack them on top of each other, cover them with the clay and start again.

After the process is over, high carbon steel billets have a carbon content of 0.7-0.8%, medium carbon billets are about 0.5-0.6% and the low carbon ones in between 0.1-0.3%. About half of the starting material is now gone due to forging.

(References:

"The Craft of the Japanese sword" by Leon and Hiroko Kapp and Yoshindo Yoshihara

The billet is then heated in the forge at a temperature of 1300 °C and when the steel has a bright white color, it is taken out and hammered gently to create a single piece. The process might be repeated more than once until the piled structure is fully welded and a single piece is formed.

The piled structure covered with the pasty mixture.

The same is done with the shingane, but instead of high carbon steel, wrought iron or low carbon steel is used.

Both billets are still be quite heterogeneous and as far as the kawagane is concerned, there is still too carbon; these problems will be addressed in the next step, which is forging&folding.

Single steel method

As I have explained above, lamination was not the single method used to make Japanese blades, nor the best one.

Swords from the 16th and previous centuries have been analyzed by various authors, to name one Cyril Stanley Smith, where the carbon content was the same throughout all the sword, around 0.5%. This mean that the blade was created with one single type of steel, just like their counterparts in other parts of the world.

With cross section, it was possible to observe a blade made without the lamination method but with a single block of material.

Were these swords inferior? No, absolutely, not in terms of strength.

In fact they didn't had the welding lines inside the material, and so no possible failure point; on the other hand, they had a softer edge which is by no means a pure disadvantage especially when said swords were supposed to be used against armor, unlike the later ones.

These swords were actually much more expensive to make, because the steel required was of high/medium carbon content and composed the entire blade rather than only the edge.

Why these swords have been ignored by most enthusiasts is still a mystery, but I won't dare to speculate in that direction.

Nowadays, smiths like Yasuhiro Kobayashi still use this method.

Another famous picture taken from the web (source); it is possible to see swords made in the medieval period being made with one piece of steel. This structure was also choose for 16th century swords as observed by other authors.

In this case the smith wouldn't make two separate billets, but just a single one, using either one single high/medium carbon type like sagegane in the piled structure or kneading together very hard carbon steel with lower carbon steel in an alternate layered structure.

Both method aim to obtain the same thing: one fairly homogeneous steel with a single medium carbon content throughout the whole blade.

The process is the same described before, so the piled structure is wrapped with the clay-ashes-paper mixture, heated and hammered into a single plate.

Once the process is over, the billet is ready to be forged and folded to create the basic shape of the sword.

This is how the heated piled structure look like; picture taken from here

(References:

"The sword and the crucible: a history of the metallurgy of European swords up to the 16th century" by Alan Williams

"The outline of Japanese Swords"

"Tatara and the Japanese sword: the science and technology" by Tatsuo Inoue

"The Craft of the Japanese sword" by Leon and Hiroko Kapp and Yoshindo Yoshihara

"The Knigth and the Blast furnaces" by Alan Williams)

Forging & Folding the steel

The other often misunderstood process about Japanese sword making is the folding , in Japanese orikaeshi kitae ( 折り返し鍛え).

Folding the steel is mandatory in order to lower the carbon content of the high carbon steel billet, homogenize the steel, reducing the number of slag inclusions and making them less harmful to the blade integrity.

Screenshot taken from the amazing video done by AWEme, source here

One of the biggest, very old misconception is that folding create a stronger steel: true, but only in a pre-industrial revolution world and I will explain why. However if the starting material is homogeneous enough, you don't need to fold the billet to create a stronger blade so folding steel in terms of functionality doesn't make any sense with anything produced by a modern age blast furnace.

Another big misconception is that folding is not necessary when an indirect steel process making is used: again true, but not before the 18th century.

Although I have already addressed the topic in the previous article, blast furnaces technology will create a better steel (in the Japanese context, the Zuku oshi tatara method) compared to a bloomery furnace, but during the fining process (turning cast iron into steel), impurities will be reintroduced in the steel and the carbon content will be uneven across the new ingots.

So even if the amount of slag would be lower, you will still have slag in the steel (namely, finery inclusions).

This is why Chinese sword making, despite using blast furnaces technology since the Han dynasty, involved folding. Actually, pretty much of the world's sword tradition used that technique to improve the quality of the steel.

Another misconception is that folding and pattern welding are the same thing; this is simply not true, the two processes are quite different in reality.

Despite of lamination/single steel being used, the process is fairly similar.

The first folding is called shitagitae (下鍛え); the steel billet is heated again to welding temperature, hammered into a plate and then the smith with the aid of his students use a blade or a similar tool to cut a notch in the middle of the plate. The cut shouldn't be able to separate the material into two blocks, but should be deep enough.

Then the plate is turned around and the two extremities hammered on top of each other, to create a single plate again.

When the steel billet is heated, it reacts with oxygen in the air and forms dark scales that are visible on the surface; it is extremely important that said scale won't end up in between the folded blocks. Those scales are rust, and having them in between the layers of the steel would be harmful to the blade structure.

To avoid that, the smith use a brush made of a wet tatami mat.

This process is repeated more than once; every time the steel is folded, it loose carbon, said element is spread evenly across the billet, and the slag inclusions are squeezed out from the material.

In fact to avoid excessive carbon loss, the billet could be wrapped again with clay.

It is also possible that folding improves the strength of the steel due to obtaining smaller grain size in the material, since it was observed that some Japanese blades had different grain size on the edge, but this doesn't seem to be the case and this fact might be related to the heath treatment instead.

It is fair to notice that is almost impossible to prevent minimum amount of rust inside the layers, and each fold while removing inclusions, it also add a little amount of harmful material. So while folding is extremely important at the beginning, after a certain level it start to be detrimental.

At the end of the process, the slag content was quite low on the best example; some steel artifacts had a % of slag closer to 0% although munition grade quality was present as well.

A billet being folded during the forging process; notice the dark scales on the surface.

After the initial shitagitae is done, the smith performs another type of folding called agegitae (上げ鍛え), which includes folding into different orientation so the cut could be done in a vertical direction or in diagonal directions.

Every time before performing a fold, the block needs to be heated at the right temperature and due to the loss of carbon it start to be harder and harder to forge; this aid the smith to understand when its time to end the process.

The optimal number of folding, which take into account the carbon loss, is around 13 if the smith is working with a high carbon billet and 10 with a low carbon steel one, although if pure iron is used the smith don't have the problem of carbon loss.

Since folding creates layers in between the steel, with an exponential growth, it adds beauty to the surface of the steel and each school create beautiful pattern that could be appreciated even nowadays. Said patterns would be revealed thanks to the Japanese art of polishing their blades.

Possible folding directions

If the smith is not satisfied with its final billet, he can cut it into 4 different pieces, stack them on top of each other, cover them with the clay and start again.

After the process is over, high carbon steel billets have a carbon content of 0.7-0.8%, medium carbon billets are about 0.5-0.6% and the low carbon ones in between 0.1-0.3%. About half of the starting material is now gone due to forging.

(References:

"Tatara and the Japanese sword: the science and technology" by Tatsuo Inoue

"The Craft of the Japanese sword" by Leon and Hiroko Kapp and Yoshindo Yoshihara

"日本刀の強度-靭性バランスと刃金用玉鋼の折返し鍛錬による炭素量,焼入れ硬さの変化" by "佐々木 直彦, 堀井 胤匡, 藤原 幹男, 斎藤 英之, 三澤 俊平"

"Ancient and historic steel in Japan, India and Europe, a non-invasive comparative study using thermal neutron diffraction" by F. Grazzi, F. Civita, A. Williams, A. Scherillo, E. Barzagli, L. Bartoli, D. Edge, M. Zoppi.)

Assembling the stock for the blade

Once all the various billets of steel are ready, the smith has to start to make the blade itself.

If he wanted to create a monosteel sword the process is quite easy, because the only thing he has to do is take his billets and start to hammering it into a long and even bar.

A much more complex and often ritualized process has to be done when the smith wanted to create a laminated sword because he has to forge weld all the various steel (namely the core and the jacket) into a single piece and then start to hammer it.

This process is called tsukurikomi (造り込み).

Two possible interpretation of the tsukurikomi; it is possible to see the various pieces of steel welded together.

Much more complex tsukurikomi were developed in the Edo period and later, and since then it become a form of art and a way to express the skill of the smith.

This process requires a lot of precision and care, because a bad weld in between the various steel could led to a catastrophic failure.

There are essentially two way in which the tsukurikomi on a kobuse style of lamination could be done; one is very basic and classic, which means encasing the shingane with the kawagane, heating them at welding temperature and then forming a single piece.

The other is to use four billets ( two sides of kawagane, one side of hagane - the edge- and the core) and carefully assemble the billets into a single composition.

Once the piled structure is at the right temperature, carefully hammering it and creating a single piece.

Now the blade is ready to be forged into shape.

Several styles of tsukurikomi; as I have explained above, not every styles have been observed yet, and most 16th century swords had either a monosteel construction or a simple lamination. Those however are the method to carefully create such composition.

"Ancient and historic steel in Japan, India and Europe, a non-invasive comparative study using thermal neutron diffraction" by F. Grazzi, F. Civita, A. Williams, A. Scherillo, E. Barzagli, L. Bartoli, D. Edge, M. Zoppi.)

Assembling the stock for the blade

Once all the various billets of steel are ready, the smith has to start to make the blade itself.

If he wanted to create a monosteel sword the process is quite easy, because the only thing he has to do is take his billets and start to hammering it into a long and even bar.

A much more complex and often ritualized process has to be done when the smith wanted to create a laminated sword because he has to forge weld all the various steel (namely the core and the jacket) into a single piece and then start to hammer it.

This process is called tsukurikomi (造り込み).

Two possible interpretation of the tsukurikomi; it is possible to see the various pieces of steel welded together.

Much more complex tsukurikomi were developed in the Edo period and later, and since then it become a form of art and a way to express the skill of the smith.

This process requires a lot of precision and care, because a bad weld in between the various steel could led to a catastrophic failure.

There are essentially two way in which the tsukurikomi on a kobuse style of lamination could be done; one is very basic and classic, which means encasing the shingane with the kawagane, heating them at welding temperature and then forming a single piece.

The other is to use four billets ( two sides of kawagane, one side of hagane - the edge- and the core) and carefully assemble the billets into a single composition.

Once the piled structure is at the right temperature, carefully hammering it and creating a single piece.

Now the blade is ready to be forged into shape.

Several styles of tsukurikomi; as I have explained above, not every styles have been observed yet, and most 16th century swords had either a monosteel construction or a simple lamination. Those however are the method to carefully create such composition.

As I have explained above, a much more complex lamination doesn't add benefits to the strength of the blade; there is still some debate but actually since we aren't able to find a definitive answer with modern physics and tests, I don't think that the smiths of 500 years ago had a better idea on how such structures would have changed the mechanical performance of the blade.

(References:

"The Craft of the Japanese sword" by Leon and Hiroko Kapp and Yoshindo Yoshihara)

Forging and designing the blade

Once that the billet is assembled and drawn into a long bar, the process of designing the blade starts.

This is were the creativity of the smith and his personal choices arise and everything in this process is related to his willing: whether he wants to create a sword, a dagger, a spear, how much curvature he wanted to put in, which kind of edge geometry he wants to use and so on.

So describing it in detail is rather impossible.

The stage in which the sword start to come together is called sunobe (素延べ) in Japanese. In this process, the sunobe is about 90% of the final length and width of the blade but is still much thicker. The shape is given through heating and hammering; the smith makes the tang and the tip as well during this stage.

It is important that the blade would be as even as possible throughout his surface, and due to using only hand power, it requires a lot of skill.

The blade being hammered into shape; taken from here

After the sunobe is done, the smith starts to work on the edge; to do so, he heath the blade at 1100 °C only at the edge and start to hammer it to give the shape he desires. He also works on the ridge of the blade and on the back.

This process is called hisukuri (火造り).After the forging and designing of the blade is completed, the smith grinds (shiage - 仕上げ) the blade in order to give an initial proper thickness to the edge. At this point much of the blade is finished because after the heath treatment you cannot remove a lot of material.

(References:

"The Craft of the Japanese sword" by Leon and Hiroko Kapp and Yoshindo Yoshihara)

Heath treating the blade: Hardening&Tempering

Swords, and any kind of edged implements, in order to achieve the highest performance available with steel need to be hardened.

This is a process that involves physical reactions to create phases of the steel that will change its mechanical performances.

There is a bit of physique involved here that I wouldn't cover in this post, since it's already too long; however, if steel gets heated at a critical temperature, and cooled rapidly (quenched) you can achieve a phase called Martensite which essentially makes the steel incredibly hard but at the same time brittle. A very hard edge would be able to stay sharp for longer period, but will be also less durable against shocks when used to cut hard materials. However, a lot of sharpness and edge durability is also related to edge geometry, edge alignment and other factors.

The problem is that if the whole sword is made of very high martensite, you would end with a glass bar; very sharp, but unsuitable for anything that involves sword's tasks.

In fact you need to temper the blade, which will reduce the hardness and thus the potential sharpness and possibly have different, much more resilient phases of steel in the other parts of the blade.

A microscopic section of Martensite; unlike with medieval steel, this phase is much more clean.

One of the key factor in Japanese bladesmithing is the selective hardening also known as differential hardening. This technique allow the blade to have different level of hardness with different steel's phases in between the edge (which will be martensite), the sides and the core (which will be pearlite and ferrite).

This is also loosely related to the fact that some swords were also made with different kind of steel: in fact in order to be hardened the steel need to have at least a medium content of carbon. With a selective hardening, it is possible to capitalize on the properties of different steels, but the final product in terms of mechanical performances shouldn't be too different from a sword made with a single type of steel which was differentially hardened too. With this type of hardening, more emphasis is given on sharpness rather than toughness at the edge.

At the same time, the rest of the blade will be quite tough and capable of withstanding damage due to the design of the blade and also due to the more resilient phases.

It is quite possible to see the differences between the two zones with the hardened edge and the rest of the blade thanks to the Japanese polishing technique; this part of the blade is called hamon (刃文) and even nowadays is still one of the major aspect of Japanese blade's aesthetic. In fact the pattern is decided by the smith and it was also used as a form of signature.

It is important for the hamon to be located on the edge and to be a rather small fractions of the blade, otherwise if very high carbon is used, you will end up with the shinto's problems.

Differential hardening seen on a real blade.

To achieve this type of hardening, the smith will perform a clay coating unique to Japan called tsuchioki (土置き).

To create the hamon, the smith has to apply a clay paste called tsuchidori (土取り) usually made with riverbed clay (for the insulation), charcoal powder (for heating control), pulverized sandstone (to prevent cracking) and other unknown elements based on different school's tradition.

Water was also added to the mixture and its only applied to the surface when its sticky enough to stay in place.

There are several ways to apply the clay, but usually the back should be thicker and on the edge few lines of clay should be applied in order to create small veins of pearlite in the edge and minimize any potential damage; these small lines are called ashi (足).

Clay being applied to a blade before heat treating.

When the clay is dry, the blade is heated until it becomes glowing red or orange (700 °C) and then quenched in boiling water. This technique is known as yaki ire (焼入れ).

To better understand the temperature of the blade, such process is done at night.

It is quite hard to get an even temperature across the blade once the clay is applied, due to its insulation properties and it's the role of the smith to get the blade heated evenly.

To achieve this result, the blade is moved upside down on the forge and he must be careful to not remove the clay with harsh movements.

Once the blade is ready, it's quenched in hot boiling water; thanks to the clay coating, different blade's part cools at different rate and the different phases of steel aforementioned are obtained through the sword.

The edge cools very rapidly while the back and the sides cool slowly; since the stress applied varied, at first a concave curvature appears and then after few seconds, the usual convex curvature appears and stay there.

It is a common misconception that the curvature of the blade is a byproduct of the heat treating; however, the smith could choose to apply some degree of curvature (convex or concave) during the sunobe process, or even after the quenching is done, in order to control the final shape. In fact, straight swords could be obtained even with this type of heath treating.

Some final thoughts: Spring tempering vs Differential hardening

If you are familiar with sword making and sword properties you might have already heard of spring tempering which is often associated with European swords of the middle ages.

In this case the blade is hardened without clay and then its tempered so the whole blade has the properties of the Japanese blade's edge and can spring back after being bent.

This technique was already used by the Chinese in the Han dynasty period, since swords of said period were excavated and had those properties.

It could be argued that one technique is superior to the other, but it's actually a matter of trade offs.

An original Chinese Jian from the Han dynasty being flexed; after the pressure is over, the blade will return to true.

A finished Japanese blade in all of its beauty.

Gunbai

(Further references I've used to make this article:"Metallurgical Research on Japanese Swords- Focusing on Swords for Practical Use- " by "Hideo Hoshi and Minoru Sasaki"

"Analysis of crystallographic structure of a Japanese sword by the pulsed neutron transmission method" by "K. Kino, N. Ayukawa, Y. Kiyanagi, T. Uchida, S. Uno, F. Grazzi, A. Scherillo"

" Neutron diffraction characterization of Japanese artworks of Tokugawa age" by " F. Grazzi & L. Bartoli & F. Civita & M. Zoppi"

"Metallurgical Microstructure of the Spear Blade Manufactured from the End of the Muromachi Period to the Edo Period" by Nahoko Sugioka, Masahiro Kitada, Masahiko Nishijima

"Time-of-flight neutron diffraction: a new analytical technique for conservation?" by Jeremy Uden, Francesco Grazzi, Francesco Civita , Antonella Scherillo , Heather Richardson, Laura Bartoli & Marco Zoppi

"From Koto age to modern times: Quantitative characterization of Japanese swords with Time of Flight Neutron Diffraction" by F. Grazzi, L. Bartoli, F. Civita, R. Francisco C. Paradowsk, A. Scherillo and M. Zoppi

"Study of Japanese sword from a viewpoint of steel strength" by M.Yaso and others

Study of Microstructures on Cross Section of Japanese sword" by M.Yaso and others)

P.S; I'm pretty sure that I've left something behind as far as references are concerned, but for anyone curious about feel free to contact me and I will give a proper list.

(References:

"Tatara and the Japanese sword: the science and technology" by Tatsuo Inoue

"The Craft of the Japanese sword" by Leon and Hiroko Kapp and Yoshindo Yoshihara)

Forging and designing the blade

Once that the billet is assembled and drawn into a long bar, the process of designing the blade starts.

This is were the creativity of the smith and his personal choices arise and everything in this process is related to his willing: whether he wants to create a sword, a dagger, a spear, how much curvature he wanted to put in, which kind of edge geometry he wants to use and so on.

So describing it in detail is rather impossible.

The stage in which the sword start to come together is called sunobe (素延べ) in Japanese. In this process, the sunobe is about 90% of the final length and width of the blade but is still much thicker. The shape is given through heating and hammering; the smith makes the tang and the tip as well during this stage.

It is important that the blade would be as even as possible throughout his surface, and due to using only hand power, it requires a lot of skill.

The blade being hammered into shape; taken from here

After the sunobe is done, the smith starts to work on the edge; to do so, he heath the blade at 1100 °C only at the edge and start to hammer it to give the shape he desires. He also works on the ridge of the blade and on the back.

This process is called hisukuri (火造り).After the forging and designing of the blade is completed, the smith grinds (shiage - 仕上げ) the blade in order to give an initial proper thickness to the edge. At this point much of the blade is finished because after the heath treatment you cannot remove a lot of material.

(References:

"The Craft of the Japanese sword" by Leon and Hiroko Kapp and Yoshindo Yoshihara)

Heath treating the blade: Hardening&Tempering

Swords, and any kind of edged implements, in order to achieve the highest performance available with steel need to be hardened.

This is a process that involves physical reactions to create phases of the steel that will change its mechanical performances.

There is a bit of physique involved here that I wouldn't cover in this post, since it's already too long; however, if steel gets heated at a critical temperature, and cooled rapidly (quenched) you can achieve a phase called Martensite which essentially makes the steel incredibly hard but at the same time brittle. A very hard edge would be able to stay sharp for longer period, but will be also less durable against shocks when used to cut hard materials. However, a lot of sharpness and edge durability is also related to edge geometry, edge alignment and other factors.

The problem is that if the whole sword is made of very high martensite, you would end with a glass bar; very sharp, but unsuitable for anything that involves sword's tasks.

In fact you need to temper the blade, which will reduce the hardness and thus the potential sharpness and possibly have different, much more resilient phases of steel in the other parts of the blade.

A microscopic section of Martensite; unlike with medieval steel, this phase is much more clean.

One of the key factor in Japanese bladesmithing is the selective hardening also known as differential hardening. This technique allow the blade to have different level of hardness with different steel's phases in between the edge (which will be martensite), the sides and the core (which will be pearlite and ferrite).

This is also loosely related to the fact that some swords were also made with different kind of steel: in fact in order to be hardened the steel need to have at least a medium content of carbon. With a selective hardening, it is possible to capitalize on the properties of different steels, but the final product in terms of mechanical performances shouldn't be too different from a sword made with a single type of steel which was differentially hardened too. With this type of hardening, more emphasis is given on sharpness rather than toughness at the edge.

At the same time, the rest of the blade will be quite tough and capable of withstanding damage due to the design of the blade and also due to the more resilient phases.

It is quite possible to see the differences between the two zones with the hardened edge and the rest of the blade thanks to the Japanese polishing technique; this part of the blade is called hamon (刃文) and even nowadays is still one of the major aspect of Japanese blade's aesthetic. In fact the pattern is decided by the smith and it was also used as a form of signature.

It is important for the hamon to be located on the edge and to be a rather small fractions of the blade, otherwise if very high carbon is used, you will end up with the shinto's problems.

Differential hardening seen on a real blade.

To achieve this type of hardening, the smith will perform a clay coating unique to Japan called tsuchioki (土置き).

To create the hamon, the smith has to apply a clay paste called tsuchidori (土取り) usually made with riverbed clay (for the insulation), charcoal powder (for heating control), pulverized sandstone (to prevent cracking) and other unknown elements based on different school's tradition.

Water was also added to the mixture and its only applied to the surface when its sticky enough to stay in place.

There are several ways to apply the clay, but usually the back should be thicker and on the edge few lines of clay should be applied in order to create small veins of pearlite in the edge and minimize any potential damage; these small lines are called ashi (足).

Clay being applied to a blade before heat treating.

When the clay is dry, the blade is heated until it becomes glowing red or orange (700 °C) and then quenched in boiling water. This technique is known as yaki ire (焼入れ).

To better understand the temperature of the blade, such process is done at night.

It is quite hard to get an even temperature across the blade once the clay is applied, due to its insulation properties and it's the role of the smith to get the blade heated evenly.

To achieve this result, the blade is moved upside down on the forge and he must be careful to not remove the clay with harsh movements.

Once the blade is ready, it's quenched in hot boiling water; thanks to the clay coating, different blade's part cools at different rate and the different phases of steel aforementioned are obtained through the sword.

The edge cools very rapidly while the back and the sides cool slowly; since the stress applied varied, at first a concave curvature appears and then after few seconds, the usual convex curvature appears and stay there.

It is a common misconception that the curvature of the blade is a byproduct of the heat treating; however, the smith could choose to apply some degree of curvature (convex or concave) during the sunobe process, or even after the quenching is done, in order to control the final shape. In fact, straight swords could be obtained even with this type of heath treating.

A katana being quenched in hot water; in the final stage, the iconic curvature appears.

Although it looks fairly simple, yaki ire is extremely hard to perform: anything from cracking, bending, warping of the blade could happen and thus the skill of the smith is essential during this stage of blade making. If something goes wrong, the blade must be heated again at 700 °C and the clay applied once again.

It is also fair to notice that every smiths inside different schools has its own yaki ire method and style.

Another very big misconception is that Japanese blades weren't tempered. This is not true for every single blade, although some blades were left untempered: this could be done only if the carbon content at the edge is not too high (something around 0.6%) because the inside and the sides of the blade would be softer and the presence of a ductile body allow the edge to be quite stable in the cut.

However, tempering was performed too although it is often unmentioned on your average Japanese sword making process.

Tempering means heating the blade again, below critical temperature and after hardening, and allow it to cools slowly or quenched again. It is often confused with hardening since the concepts are rather similar but the two techniques are the opposite.

In Japanese, the word for tempering is yakimodoshi (焼戻し) or aitori.

Every schools has its own style; usually the blade is heated again at 160-300 °C and then either quenched in hot water again or cooled on air. This technique relieves part of the stress introduced in the edge with the quench and could be repeated more than once. Every time yakimodoshi is performed, the hardness of the edge drop down a little and it's very important to avoid overtempering the sword, otherwise the hamon would disappear and the blade won't have a hard edge anymore.

Tempering allow the edge to possibly have a tempered martensite phase and increasing the strength of the blade.

A blade being tempered to lower its hardness and increasing its toughness.

Hardness value in VHP for Japanese swords are (usually, at least the ones observed) the following: 650-800 VHP for the edge, 400-300 VHP for the sides and 300-190 VHP for the core but please keep in mind that value could change a lot. It is possible that the monosteel swords made in the 16th century in Japan had lower hardness at the edge, probably around 600 VHP but hardness weren't given inside the references I've read for said swords, unfortunately.

What is also important to mention is that each phases has its own density and grain size; usually the edge and the sides are the portions of the blades with the smaller grains and thus stronger steels. Moreover, when the shock wave propagate inside the material, the difference in density of the steel reacts in different ways so the blade itself is quite hard to break or snap, but has a tendency to bend instead.

The ultimate misconception related to Japanese blade's edges is that they are extremely brittle; this is quite nonsensical.

Some tests were done on blades hardened this way and these are the results: the edge didn't take any damage at all.

Beside, there is not an optimal level of hardness in which the edge would be both sharp, capable of retaining the edge and capable of sustaining damage.

If the edge is on the hard side, it would chip; if it's on the soft side, it would roll or bend, but one thing is clear regarding Japanese blades of the 16th century: they weren't definitely weak and received phrases and respect from Chinese, Koreans and Europeans contemporary sources.

It is also fair to notice that every smiths inside different schools has its own yaki ire method and style.

Another very big misconception is that Japanese blades weren't tempered. This is not true for every single blade, although some blades were left untempered: this could be done only if the carbon content at the edge is not too high (something around 0.6%) because the inside and the sides of the blade would be softer and the presence of a ductile body allow the edge to be quite stable in the cut.

However, tempering was performed too although it is often unmentioned on your average Japanese sword making process.

Tempering means heating the blade again, below critical temperature and after hardening, and allow it to cools slowly or quenched again. It is often confused with hardening since the concepts are rather similar but the two techniques are the opposite.

In Japanese, the word for tempering is yakimodoshi (焼戻し) or aitori.

Every schools has its own style; usually the blade is heated again at 160-300 °C and then either quenched in hot water again or cooled on air. This technique relieves part of the stress introduced in the edge with the quench and could be repeated more than once. Every time yakimodoshi is performed, the hardness of the edge drop down a little and it's very important to avoid overtempering the sword, otherwise the hamon would disappear and the blade won't have a hard edge anymore.

Tempering allow the edge to possibly have a tempered martensite phase and increasing the strength of the blade.

A blade being tempered to lower its hardness and increasing its toughness.

Hardness value in VHP for Japanese swords are (usually, at least the ones observed) the following: 650-800 VHP for the edge, 400-300 VHP for the sides and 300-190 VHP for the core but please keep in mind that value could change a lot. It is possible that the monosteel swords made in the 16th century in Japan had lower hardness at the edge, probably around 600 VHP but hardness weren't given inside the references I've read for said swords, unfortunately.

What is also important to mention is that each phases has its own density and grain size; usually the edge and the sides are the portions of the blades with the smaller grains and thus stronger steels. Moreover, when the shock wave propagate inside the material, the difference in density of the steel reacts in different ways so the blade itself is quite hard to break or snap, but has a tendency to bend instead.

The ultimate misconception related to Japanese blade's edges is that they are extremely brittle; this is quite nonsensical.

Some tests were done on blades hardened this way and these are the results: the edge didn't take any damage at all.

Beside, there is not an optimal level of hardness in which the edge would be both sharp, capable of retaining the edge and capable of sustaining damage.

If the edge is on the hard side, it would chip; if it's on the soft side, it would roll or bend, but one thing is clear regarding Japanese blades of the 16th century: they weren't definitely weak and received phrases and respect from Chinese, Koreans and Europeans contemporary sources.

Some final thoughts: Spring tempering vs Differential hardening

If you are familiar with sword making and sword properties you might have already heard of spring tempering which is often associated with European swords of the middle ages.

In this case the blade is hardened without clay and then its tempered so the whole blade has the properties of the Japanese blade's edge and can spring back after being bent.

This technique was already used by the Chinese in the Han dynasty period, since swords of said period were excavated and had those properties.

It could be argued that one technique is superior to the other, but it's actually a matter of trade offs.

An original Chinese Jian from the Han dynasty being flexed; after the pressure is over, the blade will return to true.

With spring tempering, you could have a more durable blade capable of sustaining heavy loads, but its edge won't be as hard and thus cannot retain the same amount of sharpness found with differential hardening. On top of that, due to one phase being used throughout the blade, it is possible that if cracks developed, they could travel deeper inside the material since it has the same density.

More over, even spring tempered blade could take a permanent set and they are very hard to fix. It is also fair to point out that due to this properties, the blade has a tendency to move and vibrate when hitting materials, so if edge alignment is off, the cut and the thrust could fail.

On the other hand, a differentially hardened blade won't have spring properties, but it would be easier to fix if the sword take a permanent set.

The edge would be harder and capable of retaining sharpness for longer period, and it won't chip unless it would hit something harder than itself (or if the edge alignment is incredibly off). Thanks to its lack of springiness the sword is rigid and so more efficient in the cut and thrust as well as easier to use although this is more related to blade geometry.

As you can see, it's all about trade offs.

What we do know is that the Japanese knew spring tempering at least by the 16th century, as I have explained in my article about the bow. The concept that a bow could be made of steel means being able to have a spring made of steel and thus knowing how to obtaining it. Beside, once you have mastered the concepts of hardening and tempering is not that hard to discover spring tempering.

So we could guess that differential hardening was a deliberate choice when it comes to swords, to obtain a blade optimized in the cut and very sharp.

Once the blade is tempered, the smith could adjust its curvature by applying pressure with a hammer or with hands on heated copper ingot. This technique is called sorinaoshi (反り直し) and with it the blade acquires its final desired shape.

Once the blade making is over, the blade need a final grinding to obtain its final sharpness as well as polishing, decorations and assembly, so this is only the initial part of the work but I won't divagate more.

A finished Japanese blade in all of its beauty.

I hope that this very technical and detailed article was entertaining enough! It took a lot but I hope to have addressed all the misconceptions of Japanese sword making and to have teach something new even to those who already knew the process in detail.

Thank you so much for your time! Please feel free to share the article, or ask a question: I will be glad to answer in the comment.

In the next part of this series I've explained how plates were made for armor making.

Gunbai

If you are interested in buying real and authentic modern Japanese swords, I would love to recommend you these two great websites where you can chose and even customize, your sword!

They are extremely professional and their products are works of art. The process described above is still used to create this blades!